In the late 70’s and early 80’s KangaROOS was a major footwear brand, competing with the likes of Reebok and Adidas with their futuristic running shoes. With marketable features of their shoes like long-lasting materials and sole technology innovations, they had a promising future. Nowadays if KangaROOS is remembered at all, it is for the pockets they had built in to all of their shoes. If the brand had focused on different highlights of their brand, they would have been better prepared to compete in the sneaker market and create a lasting brand, instead of a fad.

Senior Capstone Project : KangaRoos

Futuristic Materials

Kangaroo leather was a long lasting and attainable material that made their running shoes a favorite of casual runners and New York Marathon winners. Their DYNACOIL sole system was revolutionary and incorporated into the astronaut boots used on the moon. It follows that if the brand would have continued to innovate in the materials they were using to make their shoes, they would have been at the forefront of 3D printing technology, like so many other shoe companies today.

Futuristic

3D printing as a manufacturing process is relatively new, but brings with it a futuristic feel that a number of sneaker companies are taking advantage of.

Adidas Futurecraft

Adidas’ groundbreaking 4D Futurecraft technology uses light to harden liquid into supportive shapes that are impossible to recreate with other more traditional methods.

Reebok Liquid Factory

Reebok’s Liquid Factory focuses on speed, and prints a large ‘web’ of an outsole that then solidifies very quickly, and is wrapped around the insole.

Nike Flyprint

Nike used 3D printing to go even lighter with their running shoes, designing shoes to be worn for only one race before they fall apart.

My project theorizes that had KangaROOS focused on marketing themselves as ‘shoes made out of futuristic materials’ instead of ‘shoes with a pocket’, they would not have been seen as a fad.

Prototyping

To show what a 3D printed sole developed by KangaRoos might look like, I looked at their previous soles and drew inspiration from the patterns they had used in the past. Using Fusion 360, I went with the idea of splitting the sole into four smaller parts that could be printed separately.

001

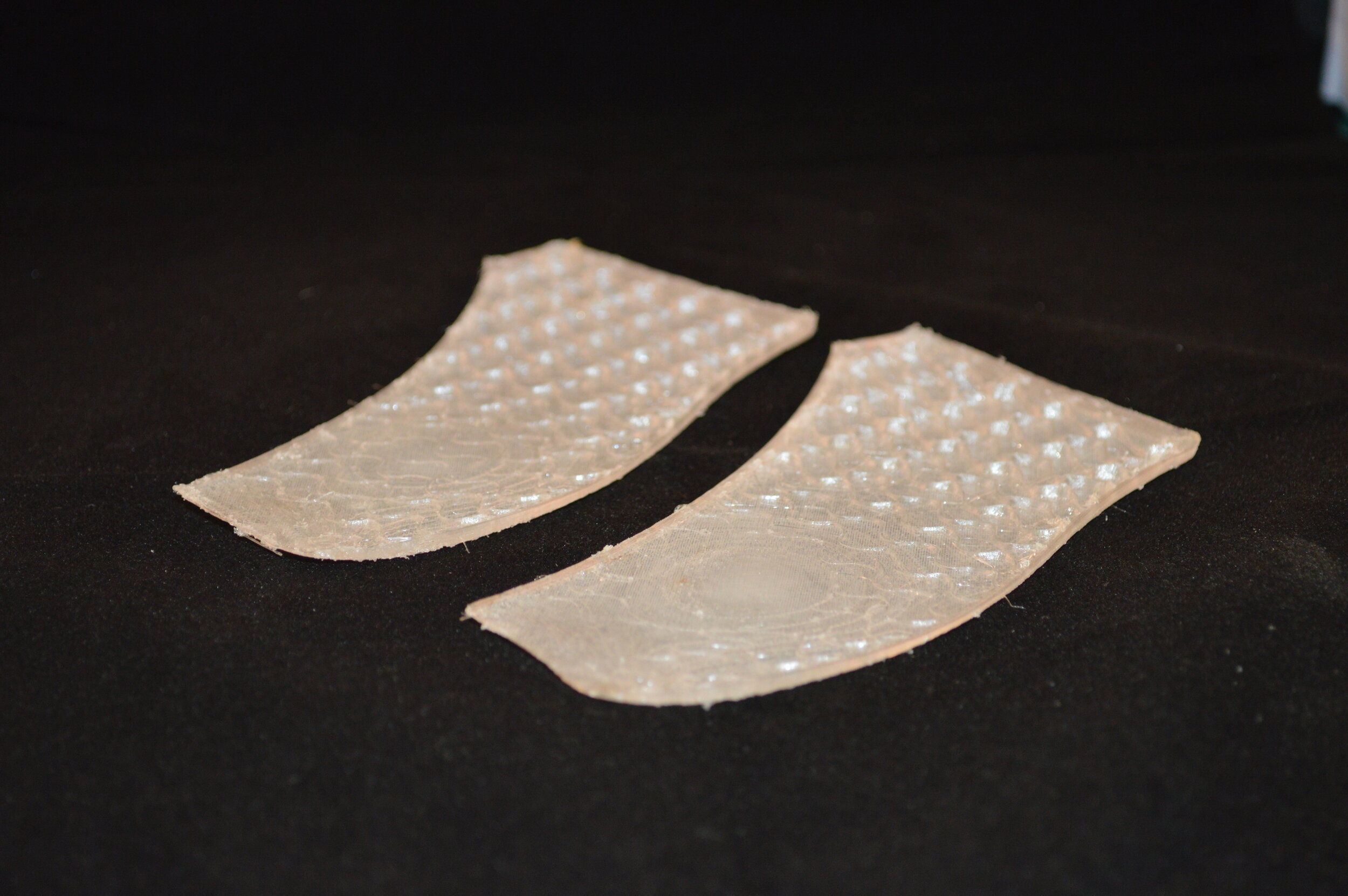

My first prototype taught me that 3D printing can be tricky. This first prototype, I dubbed “the band-aid” may not look like much, but it taught me that the material I had chosen was extremely durable.

002

My second prototype, the heel pieces, showed me that what I was attempting was possible. The grid fill that I had used provided a lot of stability and could be seen through the top and bottom, but the quality was not what I was aiming for. The top and back were very rough and the plastic I was using was tricky to sand down.

003

The third, and most frustrating prototype, taught me the most important lesson of my project. To this point, I had been printing the pieces horizontally, which made the nozzle move over the piece repeatedly, which caused the drop in quality I was noticing. It was a lot for my schools printer to handle.

004

This was the breaking point. This blob of hard plastic was waiting for me one morning after an attempted overnight print. The printer was gummed up with hardened plastic, and I had to take it apart and solder it back together before I could move on with my project. What was clear was I needed a different material and a more reliable material.

I was able to work with IC3D, an on-demand manufacturing applications workshop located in Columbus.

Their team helped me revise my model, to make for easier printing, as well as utilize their printers and materials to create much better prototypes.

005

This new model that I designed in Fusion360, allowed the four pieces to be printed vertically, which eliminated a lot of the problems I had come across with the horizontal printing design.

I used an old pair of New Balances that I had found at a thrift store that had soles that were crumbling away from age, and inserted my four piece prototype.

The four part prototype was comfortable, and provided a lot of support, but now that I had access to the superior printers and the better materials I could go begin on my final design.

006

This new two part design was easier to print, easier to assemble, could apply itself more closely to the brand language of KangaRoos than my previous design.

To create a printable pattern, I had to create the tread pattern using slopes, so that the printer could feasibly print the shapes I wanted.

I took inspiration from KangaRoos shoes from the past and applied tread at the toe and the KangaRoos logo at the front of the shoe.

Final Prototype

Bespoke

Ideally, these two halves of the sole would be printed specially for each customer. As they come into the store, they would be able to have their feet measured and, as they wait and browse the shelves, the sole could be printed for them in house, that day.

With the customer being a part of the creation process, they feel an even stronger connection to the shoes. Additionally, if they were able to create an account in the store and end up loving the shoes, they could come back after that pair has worn out and get an equally comfortable shoe with a similar upper, or one that more fits the current trends.

Benefits of 3D Printing for KangaRoos

01

KangaRoos would be able to react more quickly to trends by having multiple silhouettes and styles available.

05

As stated before, with the customer as a piece in the process, it allows them to feel connected to the shoe.

02

3D Printing feels inherently futuristic, and would help pull the brand into the next generation of sneakers.

06

Exclusivity is sought after in the sneaker market, and having a bespoke pair of 3D printed shoes creates a sense of uniqueness.

03

By using 3D Printing more, the technology would advance, and the process could evolve.

07

Using printers cuts down on labor costs and expensive mold making.

04

KangaRoos would benefit from customer input, creating accounts, and collecting foot data.

08

Encourages customers to make a profile invites them to be a part of the brand.